Supervisory Control and Data Acquisition (SCADA) is one such system which monitors and controls all kinds of field devices at remote sites. SCADA systems are usually critical as it helps in maintaining the best form of efficiency by processing and collecting real-time data.

In other words, it is a centralized system that controls and monitors the total area. The supervisory system is capable of gathering data during the procedure and sends control commands to the process.

What is the ultimate goal of the SCADA system? The main goal of this supervisory system is to supervise and control the equipments in the industrial processes for companies belonging to the private and public sectors.

You may not realize but in today’s high-tech world, there are SCADA systems nearly everywhere. Industries like manufacturing, industrial plants; oil and gas, transportation, water control, power distribution all have implemented SCADA systems. Let’s take a deeper look into this system and its uses.

SCADA – What is it?

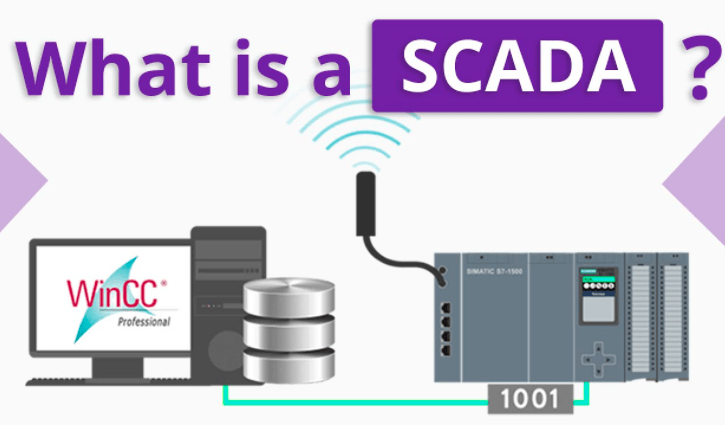

As already mentioned earlier, SCADA stands for Supervisory Control and Data Acquisition and it is a kind of process control system architecture that uses networked data communications, computers and graphical HMIs (Human Machine Interfaces) to allow a high-level supervisory control and management.

SCADA systems usually communicate with multiple other devices like programmable logic controllers and PID controllers so that the interaction with equipment and industrial process plant is there.

These systems form a huge part of control systems engineering. They integrate pieces of data and information from an analyzed process real-time. Then it logs and records the data and also represents collected data on different HMIs.

This lets the process control operators to monitor everything that is going on in the field from a distant location. It also lets the operators to control each and every process by interacting with HMI.

Main Objectives of SCADA

Let’s take a quick look at the main objectives and purposes of SCADA system.

- Oversees: SCADA systems constantly oversees and supervises the physical parameters.

- Measure: It also measures the processing parameters.

- Acquires Data: SCADA systems acquire data from Remote Terminal Units or RTY, data loggers and likes.

- Communicates Data: It helps in communicating and transmitting large amount of data between RTU and MTU units.

- Controls: It monitors real-time online and also controls the processes.

- Automates: SCADA systems also help in automatic functionality and transmission of data.

SCADA system – Major Components

The major components of a SCADA system include 3 parts. They are as follows.

Master Terminal Unit (MTU)

This is the core of the SCADA system and it consists of a computer, a PLC and a network server that lets MTU in connecting with RTUs. Later on, the MTU starts communication, collection and saving of data and helps in linking with operators and communicating data to other systems.

Remote Terminal Unit (RTU)

Being employed in field sites, each of the RTU or Remote Terminal Unit is connected with actuators and sensors. RTU is used for collecting information from the sensors and sends data to MTU. RTUs have a facility for storage capacity.

Hence, it stores data and also transmits the same when MTU sends the corresponding command. Developed units are employed with different advanced level systems that leverage RTUs and PLCs.

Communication Network

Generally, network means connection. Whenever you tell a communication network, this is defined as a link between MTU in the central location and RTU in the main field.

This wireless communication channel is utilized for networking purposes. There are other mediums of communication like twisted pair cables and fiber optic cables that are also used.

SCADA systems – Main functions

SCADA system is a collaboration of software and hardware components that allow manufacturing units for performing definite functions. Few of the pivotal functions include.

- Monitoring and gathering real time data.

- Interacting with control stations and field devices through Human Machine Interface.

- Recording systems events within the log file.

- Controlling manufacturing procedure virtually.

- Storing reports and information.

So, if you think you need to implement SCADA systems within your office, this is possibly the best solution. Make sure you plan the perfect SCADA solution for your office so that you can get the best possible results.